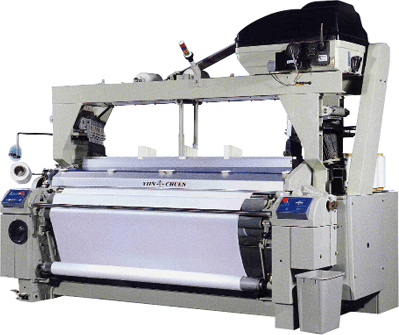

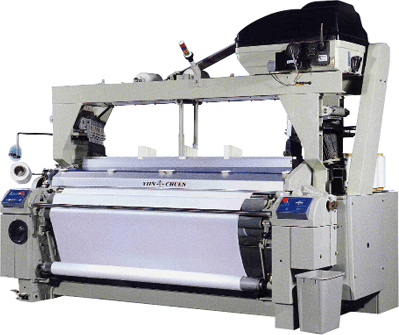

A loom is a machine to weave cloth with yarns.

You can weave cloth by inserting weft yarns into between the warp yarns pulled upward and downward. The inserted yarns are beaten with a reed moving back and forth. By repeating the movements, cloth will be made. Originally, all these processes were carried out by human hands. However now, most of cloth is woven by an automated machine for higher productivity. Around five hundred to one thousand weft yarns are inserted and beaten in just one minute. The width of the woven cloth usually measures from 1.3m upto 3.5m.

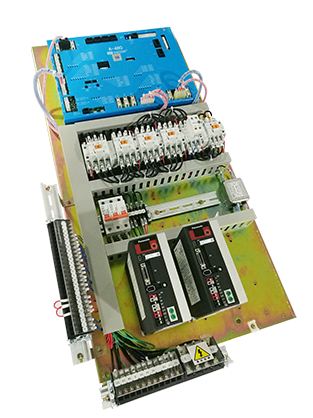

Types of looms differ diversely, and we are a developer, maker, and seller of a controller for the loom called a jet loom. Circuit board and micro computer software are also designed by ourselves.

Jet looms harness water or compressed air to insert a weft yarn. The one using water is called a water jet loom, and the other using compressed air is called an air jet loom.

Water jet looms are mainly used to weave cloth made of chemical fibers. The woven cloth turns into an umbrella, suit lining, curtain, textile for industrial purpose, and so on. A pump is set to this type of looms and splashes out water to carry a weft yarn.

On the other hand, an air jet loom weaves cloth made of natural fibers like cotton. The woven cloth turns into products such as a shirt and bed sheet. This type of looms inserts a weft yarn with compressed air provided through an air compressor. Since air can't carry a weft yarn as far as water does, electromagnetic air valves are attached to the looms and relay air to carry a weft yarn.

Jet looms are highly mechanized and work very fast. They work under precise timing and sensoring controls. We have manufactured the loom controllers for a long time and the experiences must guarantee the quality and performance. Each of our loom controller is given special protections against humidity and expected to work in harsh environments. Our controllers are sure to serve you for a long time.

HOKUETSU DENKEN

HOKUETSU DENKEN